Presently, cryogenic turbo-expander technology is the dominant NGL recovery process and it is used throughout the world. Successful gas processors will be those who adopt technologies that are less energy intensive, have lower capital and operating costs and offer the flexibility to tailor the plant performance to maximize product revenue as market conditions change, while maintaining overall system efficiency. However, rising natural gas prices have dramatically reduced the economic incentive to extract NGLs from domestically produced natural gas. The revenue derived from extracting NGLs is crucial to ensuring the overall profitability of the domestic natural gas production industry and therefore of ensuring a secure and reliable supply in the 48 contiguous states. Historically, the commercial value of the separated NGL components has been greater than the thermal value of these liquids in the gas. NGL is a collective term for C2+ hydrocarbons present in the natural gas.

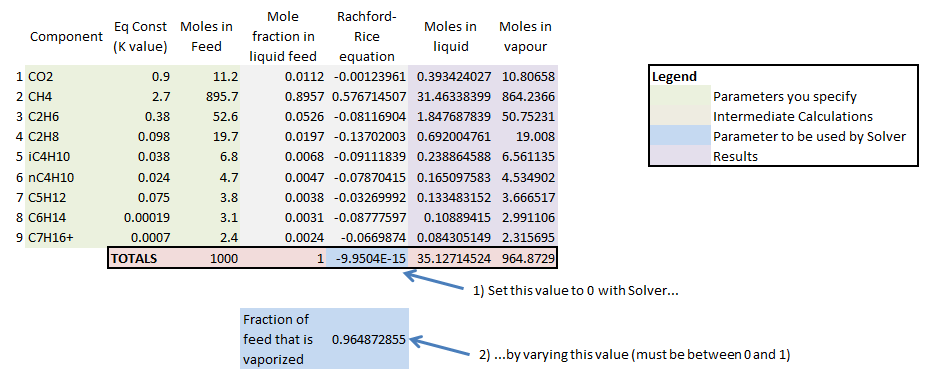

Depriester chart calculator software#

Specific goals and objectives of the overall program include: (i) collecting relevant physical property and Vapor Liquid Equilibrium (VLE) data for the design and evaluation of the new technology, (ii) solving critical R&D issues including the identification of suitable dehydration and NGL absorbing solvents, inhibiting corrosion, and specifying proper packing structure and materials, (iii) designing, construction and operation of bench and pilot-scale units to verify design performance, (iv) computer simulation of the process using commercial software simulation platforms such as Aspen-Plus and HYSYS, and (v) preparation of a commercialization plan and more » identification of industrial partners that are interested in utilizing the new technology. When successfully developed, this technology will benefit the petrochemical industry, which uses NGL as feedstocks, and will also benefit other chemical industries that utilize gas-liquid separation and distillation under similar operating conditions.

6,553,784, which if commercialized, has the potential of achieving substantial energy savings compared to currently used cryogenic technology. The new process, known as the IROA process, is based on U.S. The overall objective of this project is to develop a new low-cost and energy efficient Natural Gas Liquid (NGL) recovery process - through a combination of theoretical, bench-scale and pilot-scale testing - so that it could be offered to the natural gas industry for commercialization.

0 kommentar(er)

0 kommentar(er)